Modern vehicle diesel engines are a gem, they produce more power, are fuel efficient and environmentally friendly. But this all-round performance will deteriorate over time, even if regular garage maintenance is carried out.

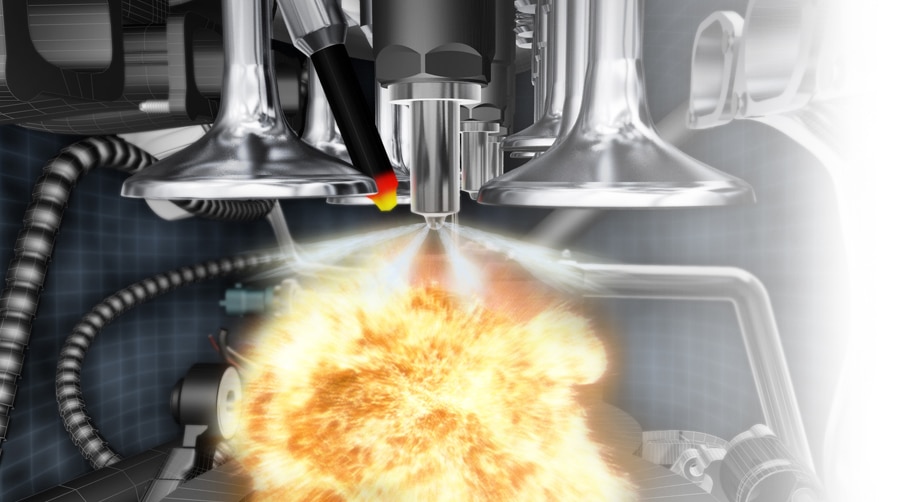

Let’s look at why. A common rail diesel engine found in most modern cars and trucks compresses a mixture of diesel and oxygen at extreme pressures, causing combustion. This combustion creates exhaust gasses which contains a high concentration of oxygen that will react with nitrogen, creating oxides of nitrogen (NOx), a pollutant that helps create smog, acid rain, and ground level ozone. In order to reduce NOx to meet strict emissions rules, the diesel engine uses an exhaust gas recirculation (EGR) valve that diverts some of these gasses back to the engines intake. This drops the concentration of oxygen in the intake manifold, reducing NOx output and lowering combustion temperatures.

Another force in play here is the positive crankcase pressure caused by internal combustion. The downward strokes of the pistons create positive air pressure in the crankcase. Blow by gasses are added to the crankcase as well due to the combustion process. These gasses in the crankcase often contain hydrocarbons, carbon monoxide, water condensation, NOx, and vaporised oil droplets. Due to strict emissions controls, these cannot be vented into the atmosphere, and are instead fed back into the intake to be burnt once more.

The combination of EGR and crankcase gasses inside the manifold create soot, oil, and other sorts of sludge. This travels into the combustion chamber causing a less efficient complete burn of the diesel fuel, it cakes the back of the vales and the poorly burnt up sludge will then make there way into the diesel particulate filter (DPF) causing a build up of unwanted dirty matter in this expensive emissions control device that then needs to burnt off by extra regenerations. These regenerations often don’t happen due to the nature of how we use our vehicles for short trips and the DPF starts blocking up and the vehicles fuel efficiency drops away.

Combine this with fuel injectors which are dealing with poorer quality diesel fuels from petrol forecourts and water contamination built up in the fuel filter housing the injector itself can stop operating at its correct rate of fuel spray pattern meaning fuel burn in the combustion camber is effected and again drives down fuel economy.

SO what can vehicle owners do to combat these issues? Well there is simple easy maintenance step available to Diesel vehicle owners which is Dipetane Fuel Treatment.

Dipetane treated fuel has a unique ability to burn carbon more completely compared to all standard fuels meaning that much less unburnt carbon enters the DPF and therefore the regeneration occurs less often. As an example, in some truck 6 liter engines Dipetane’s use has extended the regeneration from 70 hours out to over 200 hours. This is a substantial fuel saving and protects the DPF from the very high temperatures involved in the regeneration process. This also keeps the combustion chamber of each cylinder cleaner and more efficient and cleans the nozel of the fuel injector resulting in better spay patterns and a more complete burn of fuel.

So, what’s the bottom line? Using Dipetane on a monthly basis will save you money in costly repairs, provide better fuel economy and help produce a cleaner environment through less toxic emissions.

Click the link to see where to buy .. https://dipetane.com/where-to-buy/